Recommemded Industry and Workpiece

Grinding machine Cutters Cutters for crusherGrinding machine Molds Steel and mold plates

Grinding machine Liquid crystal and semiconductor parts Glass for semiconductor (Fused quartz)

Grinding machine Various machine parts Hydraulic valves/Industrial compressor valves/Compressors for household appliances

Grinding machine Refractory bricks (Ceramics)

New product SVR80

Space-saving even with the table traverse type while demonstrating excellent productivity and precision

Wide opening

The door opening part is designed to be wide to facilitate the easy removal of workpieces with a maximum swing of 820 mm.

Improved operability with a tilting control panel

The control panel adopts a design that allows it to be tilted as a standard and the operability has been improved.

Feature of SVR Series

Easy operation

- Grinding parameter can be easily by key-bord.

- To reduce the air cut time and improve safety in grinding operation,

- Spark on control device and Automatic overlaod retracting device are equipped as standard accessories.

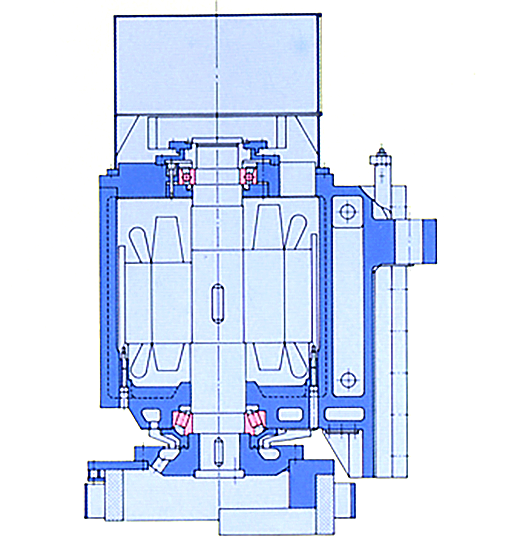

High accuracy and High rigidity

- Spindle is supported by ultra-precision bearing.

- column is fasten to the bed at three points and this 3-point column support provides for slight adjustment of the spindle relative to the chuck.

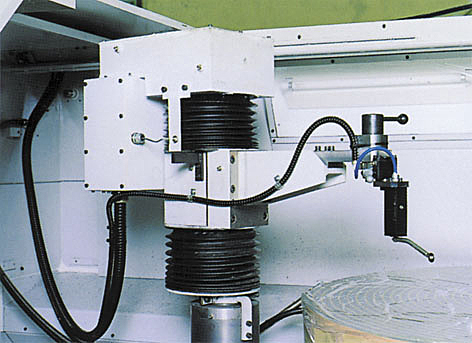

Grinding head and feed device

- Spindle is supported by ultra-precision bearings with pre-load to improve rigidity.

- Head vertical feed is driven by AC servo motor.

- Head vertical feed is able o select step feed or continuous feed according to various materials of work pieces.

Base and magnetic chuck

- The slide-ways of base are lubricated automatically while tabel traverse and magnetic chuck table is lubricated with oil-bath.

- Magnetic chuck table moves between grindingposition and setting position for easy setting of work pieces.

- Magnetic chuck speed is continuously variable,so the best grinding condition can be set.

- Magnetic chuck force is continuously variable,so the warp of work piece can be ground.

column

・Column is rigid box type cast iron and fasten to the bed at three points.This 3-points column support provides for slight adjustment of the spindle relative to the chuck.

Operating panel

- Grinding parameter, rough and fine feed rate, feed volume, retract volume after grinding and etc. can be set easily by key-bord watching CRT. The position of grinding head is displayed on CRT.

- By using manual pulse handwheel, manual infeed is operated easily and exactly.

Selection of optional accessories

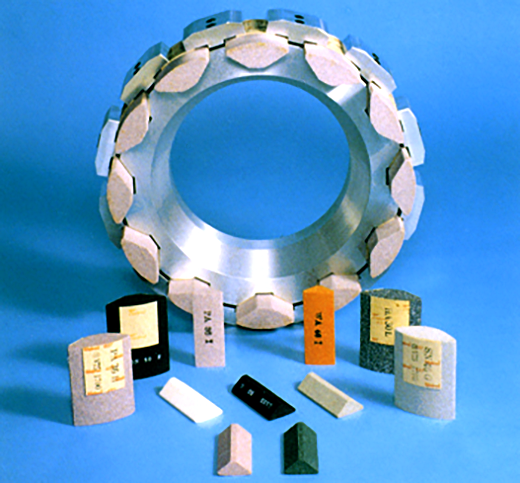

Grinding wheel flange

Standard accessory is triangle segment wheel flange. Other wheel flange for CBN or Diamond wheel will need according to materials of work pieces.

Direct measuring device

Direct measuring device is need according to output volume or tolerance of work pieces.

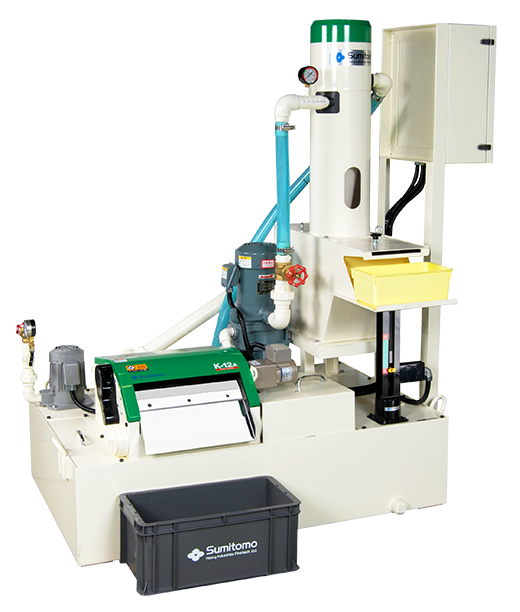

Coolant separator

Should be select one coolant separator system.

In case of magnetize work pieces, basic selection is magnetic separator with the coolant tank.

In case of non-magnetize work pieces, paper filter type or centrifugal separator type is suitable.

Mist collector

In addition to the standard specification full cover (SVR 160 or more is a special accessory), dust collector is indispensable for consideration to factory environment.

Direct measuring device

CNC setting system of measuring device (electric control)

(electric control)

Mist collector

Coolant separator

Case study

Product specifications

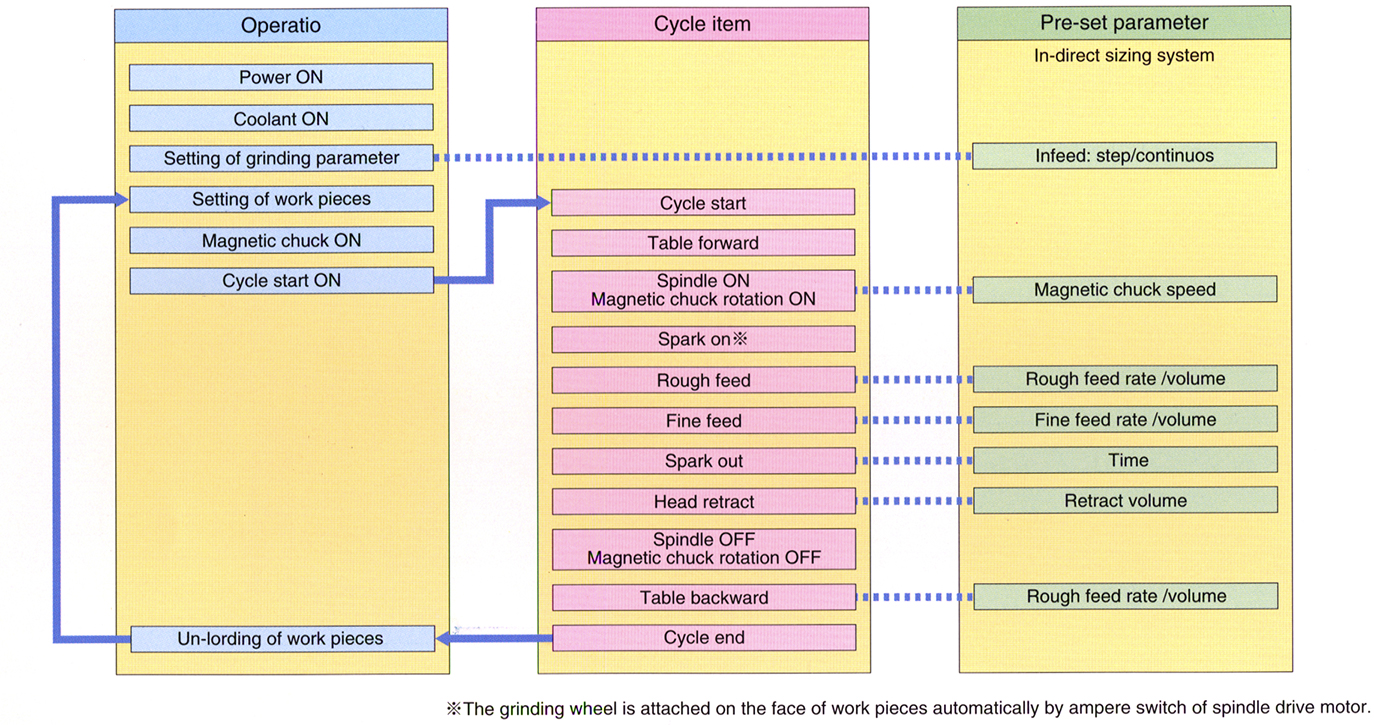

Automatic cycle grinding system

The standard specification of this machine is an indirect sized automatic cycle grinding system.

In addition, direct sizing equipment (limit switch type, electronic control type) can also be adopted by special specifications.

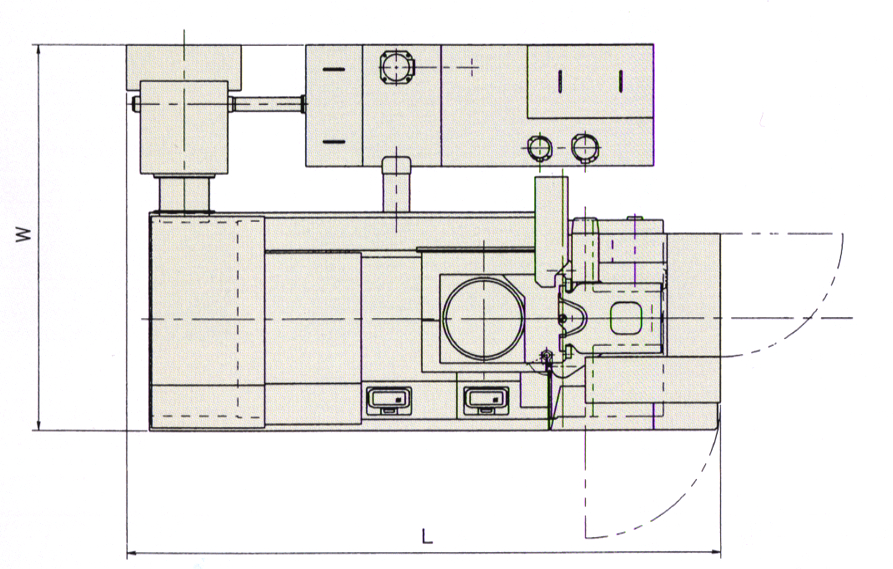

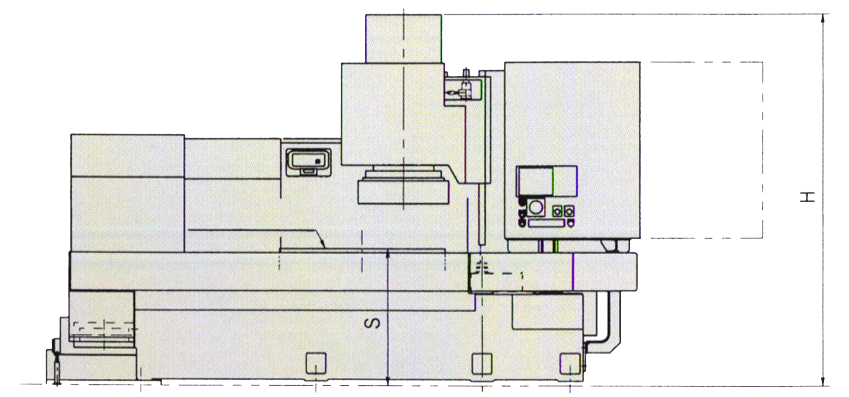

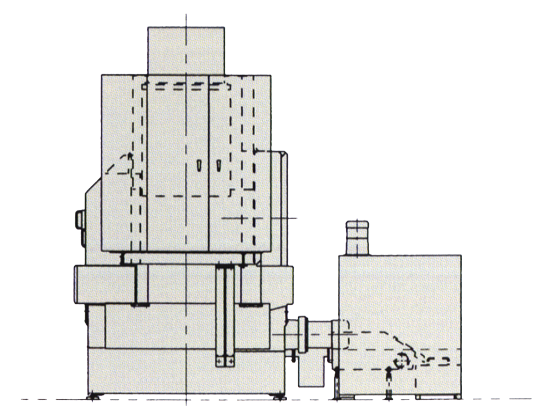

Machine layout

| Type | L | W | H | S |

|---|---|---|---|---|

| SVR60 | 2500 | 1900 | 2050 | 890 |

| SVR80 | 3000 | 2500 | 2000 | 923 |

| SVR110 | 4000 | 3200 | 2500 | 910 |

| SVR130 | 4100 | 3400 | 2600 | 910 |

| SVR160 | 5500 | 3600 | 3600 | 1185 |

| SVR180 | 5800 | 3700 | 3600 | 1185 |

| SVR200 | 6200 | 4700 | 3600 | 1185 |

Note) The shape is different according to type.

Machine specifications

| item | unit | SVR60 | SVR80 | SVR110 | SVR130 | SVR160 | SVR180 | SVR200 |

|---|---|---|---|---|---|---|---|---|

| Magnetic chuck table diameter | mm | 600 | 800 | 1100 | 1300 | 1600 | 1800 | 2000 |

| Max. swing in water guard | mm | 620 | 850 | 1200 | 1500 | 1800 | 2000 | 2300 |

| Max. grinding height (when the depth of grinding wheel face from holder bottom is 10mm) | mm | 280 | 300 | 370(670) | 640(940) | 640 | ||

| Permissible weight of work | kg | 200 | 300 | 1500 | 3000 | |||

| Magnetic chuck table speed (variable) | mm | 12-60 | 8-40 | 5-30 | 3-15 | |||

| Grinding wheel diameter | mm | 330 | 450 | 600 | 700 | 840 | 935 | 1065 |

| Spindle speed(50Hz/60Hz) | mm | 980/1170 | 720/870 | 720/700 | 580/575 | 480/490 | 410/430 | 410/430 |

| Head automatic feed rate | mm/min | 0.1-1.5 | ||||||

| Head travel speed | mm/min | 300 | 400 | |||||

| Handwheel infeed | mm/div | 0.001 | ||||||

| Spindle drive motor | kw | 11 | 22 | 37 | 45 | 55(75) | 75 | |

| Grinding head drive motor | kw | 1.0 | 1.6 | 3.0 | 4.5 | |||

| Magnetic chuck drive motor | kw | 1.5 | 3.7 | 7.5 | ||||

| Table traverse motor | kw | 0.4 | 0.75 | 1.5 | ||||

| Coolant pump | kw | 0.25+0.18+0.1 | 0.75+0.4+0.25 | 1.5+0.75+0.75 | ||||

| Magnetic coolant separator | kw | 0.025 | 0.06 | |||||

| Max. height of machine | mm | 2050 | 2000 | 2500(2800) | 2600(2900) | 3600(3900) | 3600 | |

| Floor space | mm | 2500×1900 | 3000×2500 | 4000×3200 | 4100×3400 | 5500×3600 | 5800×3700 | 6200×4700 |

| Weight of machine body | kg | 3000 | 5000 | 7800 | 8400 | 17000 | 18000 | 22500 |

( ) Is a special specification. This use is subject to change without prior notice for machine improvement.

Standard accessories

- Automatic cycle grinding system (indirect sizing system)

- Manual pulse generator

- Spark on control device

- Automatic overload retracting device

- Grinding head position display (LCD)

- Star-delta spindle start unit (except SVR60)

- Magnetic chuck

- Magnetic neutrofier and magnetic force controller

- Manual grease pump (cartridge type)

- Wheel brake system

- Inverter of table rotation drive motor

- Splash guard (SVR60-130 full covered type/SVR160-200 upside open type)

- Segment wheel holder

- Segment wheel (for self grinding of chuck face)

- Wheel dresser

- Work light

- Standard work tool

- Installation parts (bed-adjusting bolts and sole plates)

- Coolant hose for table cleaning

Optional accessories

Function addition

- Direct measuring device (Marposs)

- CNC setting system of measuring device(Electronically controlled type)

- Another place coolant device (with magnetic coolant separator)

- Coolant temperatire control device

- Magnetic chuck (Air-up type)

- Magnetic chuck (narrow pitch pole type)

- Mist collector

- Grinding wheel flange (cylindrical type)

- Grinding wheel flange (for CBN wheel or diamond wheel)

- Guide ring

- Foot switch (for table rotation inching)

- Rotating lamp/Rotating lamp(3-color)

- Spark on control device(AE sensor type)

- Frequency converter for spindle rotation

- Table feed 2 axis control specification

For function change

- Paper filter type coolant separator

- Magnetic coolant separator with paper filter

- Magnetic coolant separator with cyclone separator

- Centrifugal type coolant separator (batch type)

- Centrifugal type coolant separator (semi-automatic type)

- Centrifugal type coolant separator (fully automatic type)

- Automatic grease pump

- Customers color