Recommended Industry and Workpiece

Coolant processing equipment Linear motion devices Linear systems/Linear guides/Ball screwsCoolant processing equipment Bearing parts Robots/Automotives/Construction machines

Coolant processing equipment Iron manufacture Crank shafts/Rolls for iron manufacture/Oxide scale

Coolant processing equipment Construction machines and construction machine parts Engine/Transmission/Hydraulic parts

Coolant processing equipment Automotives/Automotive parts/Motorcycle parts Engine/Transmission/Fuel injection systems

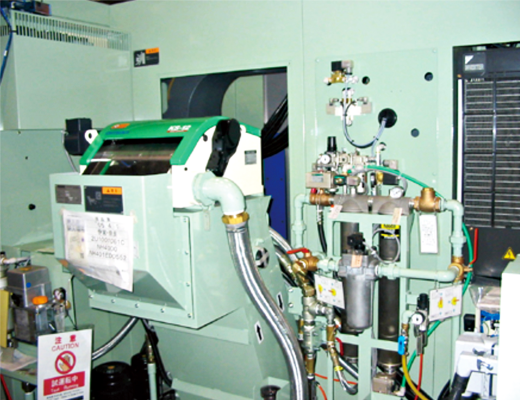

Product characteristics

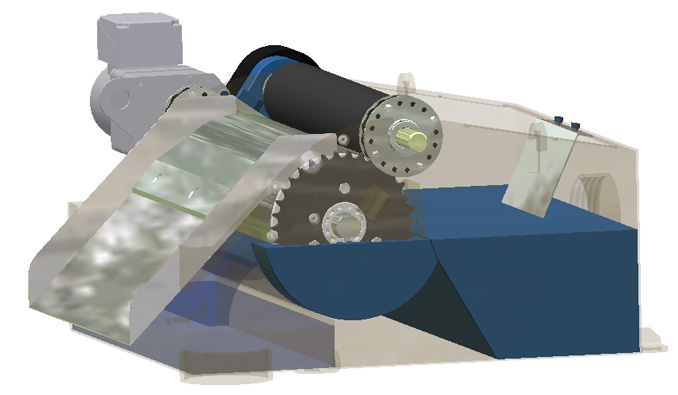

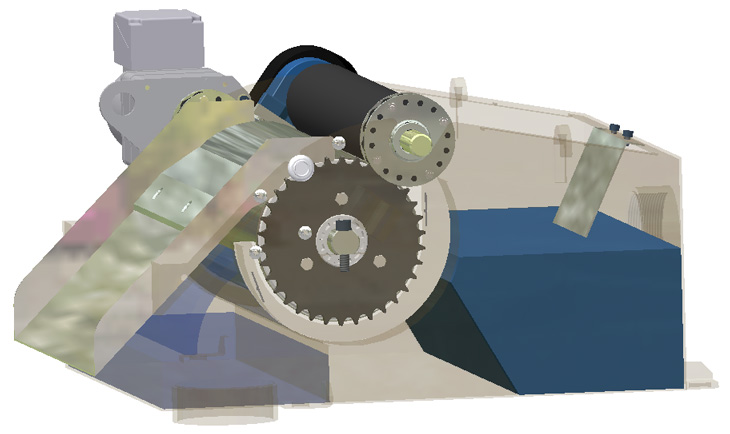

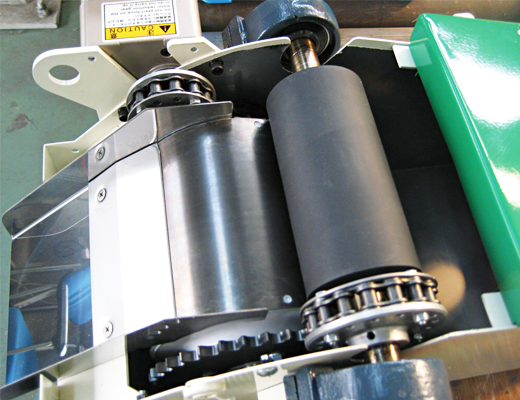

Outstanding durability for the Drive System! (PAT.)

- Frame design investigated and wear resistance in actual use has improved sufficiently.

- Succeeded to avoid grinding wheel grits from sprockets, and prevent the trouble of magnetic drum parts.

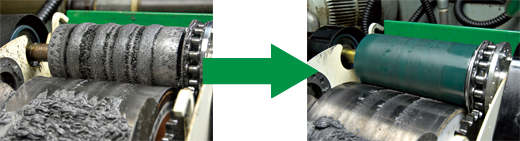

Surface of the Magnet Drum is especially hardened!

- There are no scratch on the surface of the Magnet drum!

- Filtering and squeezing performance is stable for a long term.

- Squeeze roller is also not scratched.

Forced drive mechanism for the Squeeze Roller!

Squeeze roller does not slip for this remarkable mechanism and led to saving more coolant liquid.

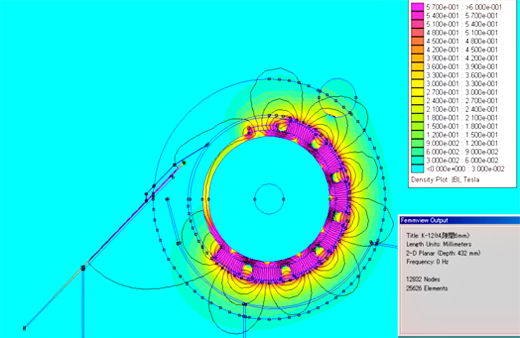

Precise Magnet Arrangement based on magnetic field analysis!

Attracting power of the magnet is stronger than ever for its special arrangements based on a scientific study. Sludge can be recovered efficiently.

Movie

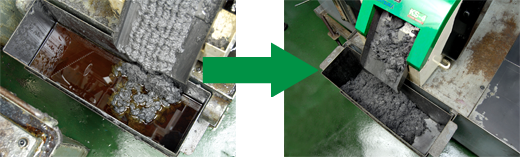

Secondary filteration Modes: Benefits of installing the KS and KSD models

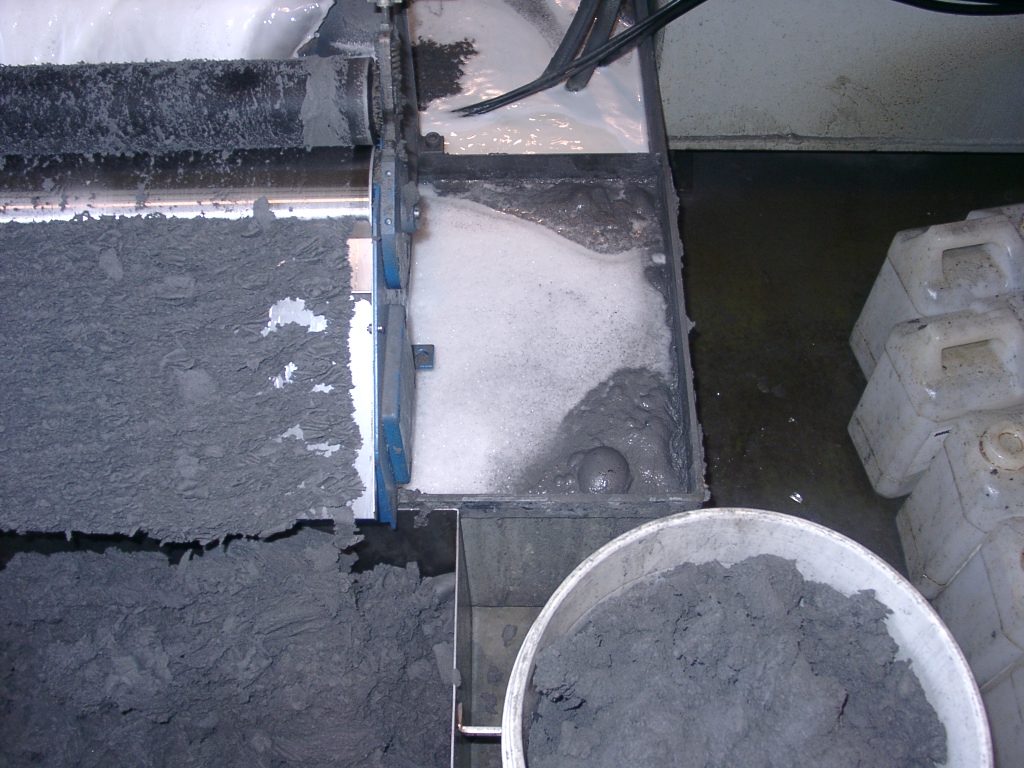

Large amount of muddy sludge will remain when cutting cast iron.

FINE MAG can separate almost 90% of the muddy sludge.(*Muddy sludge which is under 100 μ and 90% at weight ratio.)

Large amount of very fine muddy sludge will be generated when cutting cast iron which is the same as grinding.These fine muddy sludge will damage the machine tools, pumps, blades, etc., if it is not removed.

Casting Cutting Sludge

Muddy sluge could not been separated by the drum filter of the chip conveyors because it is very fine.

When FINE MAG is introduced for secondary filtration,

Benefits 1

- Breakdown of the machine is prevented.

- Tertiary filter life will extend.

- Product defect ratio will decrease.

- Blade life will extend.

- Almost no need of maintenance.

Benefits 2

- More than 90% of sludge is separated.(Weight ratio)

- No extra cost for consumables.

- Sludge condition is dry.

- No need of high pressure cyclone pump and will reduce CO2 emission.

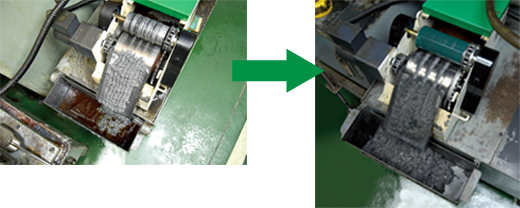

Shaving Process Model : Benefits of installing the KS and KSD models

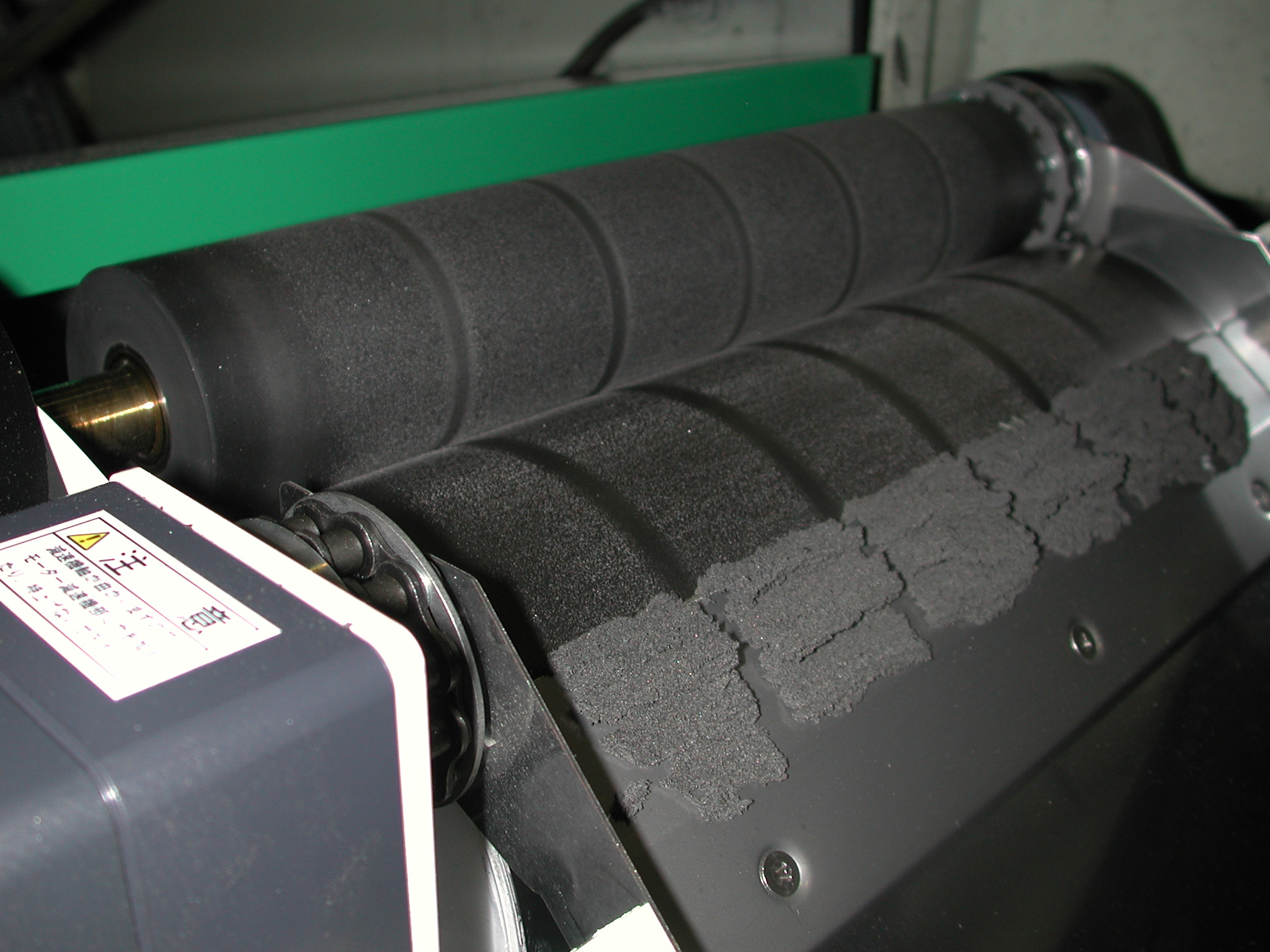

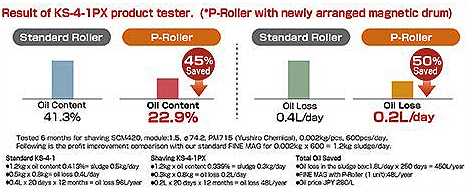

P-Roller and the new magnet arrangement reduced the amount of chips that has been stuck to the squeeze roller.

Example of Shaving Chips

Factory cleanliness

Oil content 41.3% 22.9%

Oil loss 0.4L/day 0.2L/day

※Penetration-free material which will push back the sharp chips.

Marvelous durability

Chips stuck in roller.

Three months later

Chips does not get stuck easily.

One year later

Excellent squeezing result

Well squeezed sludge in the box.

Result of KS-4-1 PX product tester.(*P-Roller with newly arranged magnetic drum)

FINE MAG Series: Product Line Up

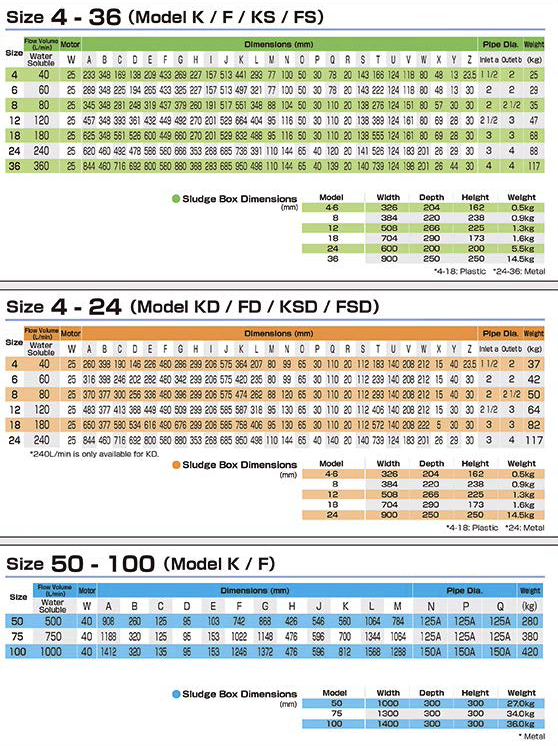

Model K/F (magnetic drum diameter: φ140 mm for models 4 to 18 and φ216 mm for models 24 to 36)

Standard type (Fine chips)

Features

- Model K is rare earth magnet type which has ten times more magnetic power of ferrite magnet.

- Model F is ferrite magnet type.

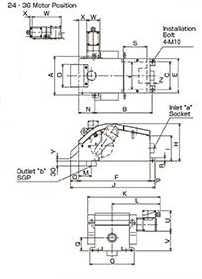

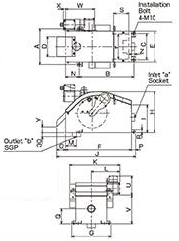

type KS・type FS (magnetic drum diameter: φ140 mm for models 4 to 18 and φ216 mm for models 24 to 36)

Secondary Filtration for Cutting/Shaving Process Type

Features

- Effective design based on the analysis of magnet arrangement and shape which improved the attracting power of the magnet.

- Amount of chips stuck on the squeeze roller is reduced and the performance improved.

- Blade life will extend and the product defect ratio will decrease.

Practical Usage of FINE MAG

- Secondary filtration of veryfine muddy sludge for cutting cast iron.

- Filtration of shaving process coolant liquid.

- Filtration of magnetic sludge which is contained in the coolant from the centrifugal oil separator.

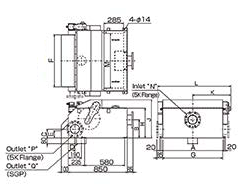

type KD・type FD(magnetic drum diameter: φ216 mm)

High Filtration Efficiency Type

Features

- Filtering performance has improved by making the magnetic drum larger.

- Best model for the fine chip sludge from lapping and honing. Also, for the sludge from the induction hardening that does not attract very well to the magnets.

type KSD・type FSDmagnetic drum diameter: φ216 mm)

High Filtration Efficiency and Secondary Filtration for Cutting/Shaving Process Type

Features

Large magnetic drum has higher filtering efficiency than Model KS/FS.

type K・type F(magnetic drum outer diameter: 319 mm)

Large Capacity Type

Features

- 500 L/min to 1,000 L/min available.

- Model K is rare earth magnet type which has ten times more magnetic power of ferrite magnet.

- Model F is ferrite magnet type.

- Model KS/FS are aiso available.

- Please contact us for details.

Model K : Rare Earth Magnet

10 Times Powerful Magnet

Rare earth magnet has ten times more magnetic power of ferrite magnet. Which enables to collect difficult magnetized sludge even with high viscosity coolant.

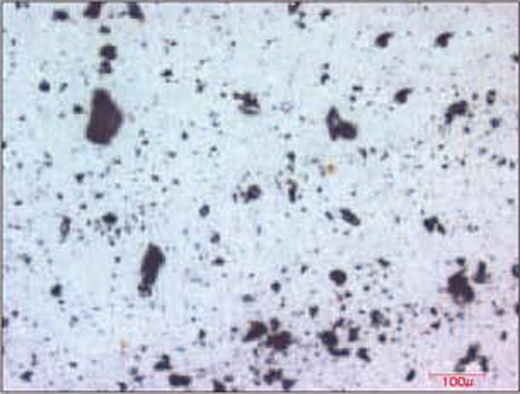

Sludge example of Model K-36

- Secondary filter becomes unnecessary.

- Tank cleaning frequency reduced to half.

- Coolant life has doubled.

- Work: Drive Shaft (SCr420)

- Coolant: Oil based

- Machine: Gear Grinder

Model F : Ferrite Magnet

Economical type for general process and materials. Attracting power of the magnet has improved by special magnet arrangement. For sludge that will attract to magnets very well.

Sludge example of Model F-4

- Abrasive wheel life has doubled.

- Filter change frequency of secondary filter reduced to half.

- Scratch on the product reduced.

- Work: Machine Parts (S65C)

- Coolant: Water soluble

- Machine: Cylindrical grinder

Case Study

Product specifications

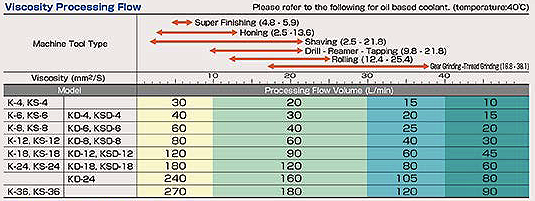

Viscosity Processing Flow

Please refer to the following for oil based coolant (temperature 40℃).

Machine Selection (By application)

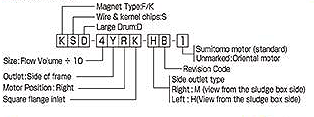

Model Code

Leg Dimensions (4 legs per unit bolts are M12)

Options

- P-Rollers

- Legs

Standard Specifications

| Outlet: Bottom of frame | |

| Motor | Position: Left (when viewed from the scraper side) |

| Voltage: AC200V 50/60Hz 3ph | |

| Current: 25 W 200V 50/60Hz: 0.25/0.22A (CE・UL・CCC Compliant) 220V 50/60Hz: 0.26/0.23A (CE・UL・CCC Compliant) |

|

| Current: 40W 200V 50/60Hz: 0.31A/0.28A (does not meet overseas standards) 220V 60Hz: 0.28A |

|

| Reduction ratio: 1/1000 size 4 to 36 (All models) | |

| Reduction ratio: 1/900 size 50 to 100 (All models) | |

| Accessory:One sludge box | |

Special Specifications

- Voltage: 380V・400V・415V・440V 50/60Hz

(CE・CCC Compliant) - Square flange inlet

※Please contact us for further information.

Caution

Make sure to read and understand the manual thoroughly before operating this product

※Product test result is an example. Actual results many differ according to the conditions.