Recommended Industry and Workpiece

Coolant processing equipment Liquid crystal and semiconductor parts Non-ferrous metal and resinCoolant processing equipment Construction machines and construction machine parts Engine parts/Non-ferrous metal/SUS/Aluminum/Abrasive grain recovery

Coolant processing equipment Automotives/Automotive parts/Motorcycle parts Engine parts/Non-ferrous metal/SUS/Aluminum/Abrasive grain recovery

Movie

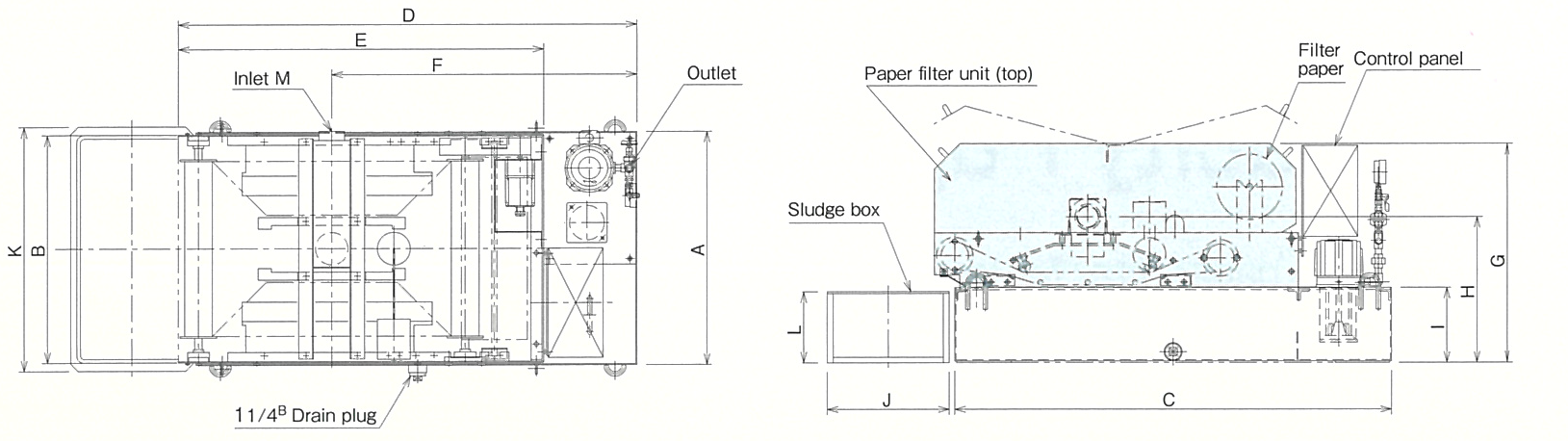

SP series Paper Filter

- Separator to clean coolant using a filter paper

- Filter paper can be varied to allow passage of mean particle sizes ranging from 10μ to 95 μ

Applications

- Various grinding machines

- Honing machines

- Superfinishing machines

- Cold rolling machines

- Wire drawing machines

- Washing machines

- Pelletizers

- Roll forming machines

- Secondary filtration for various cutting processes

Magnetic and non-magnetic

sludge

Structure

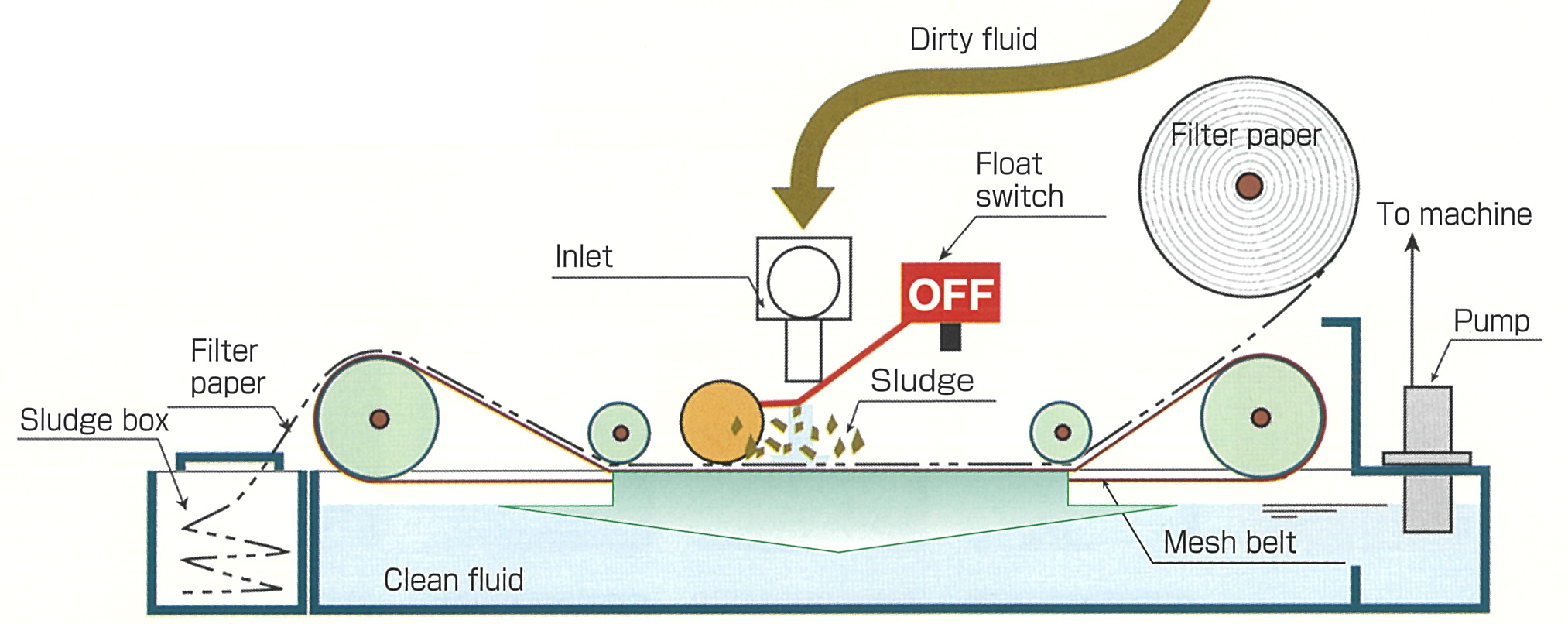

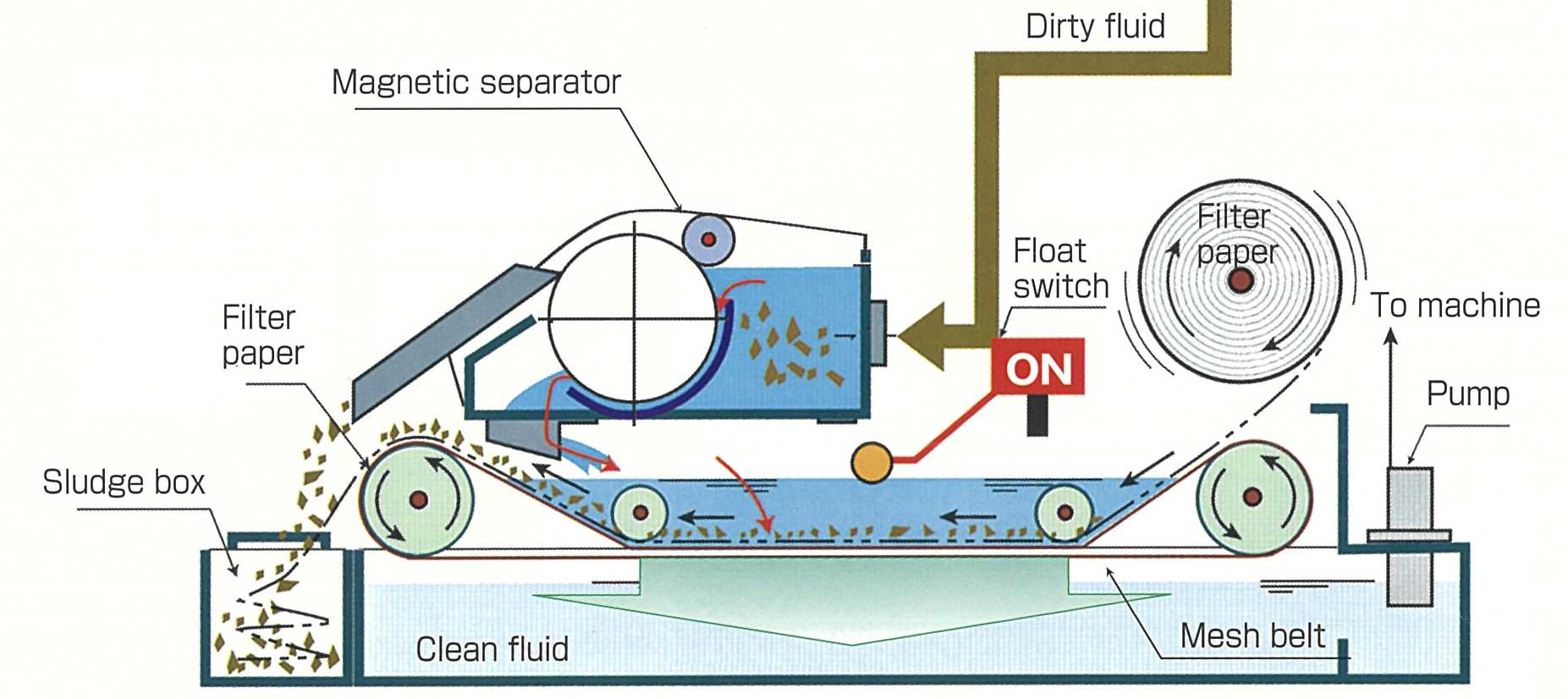

Dirty coolant is filtered using a filter paper.

- Dirty coolant is filtered using a filter paper.

- When the coolant level drops back down, the float switch is turned off and the paper filter will stop rolling.

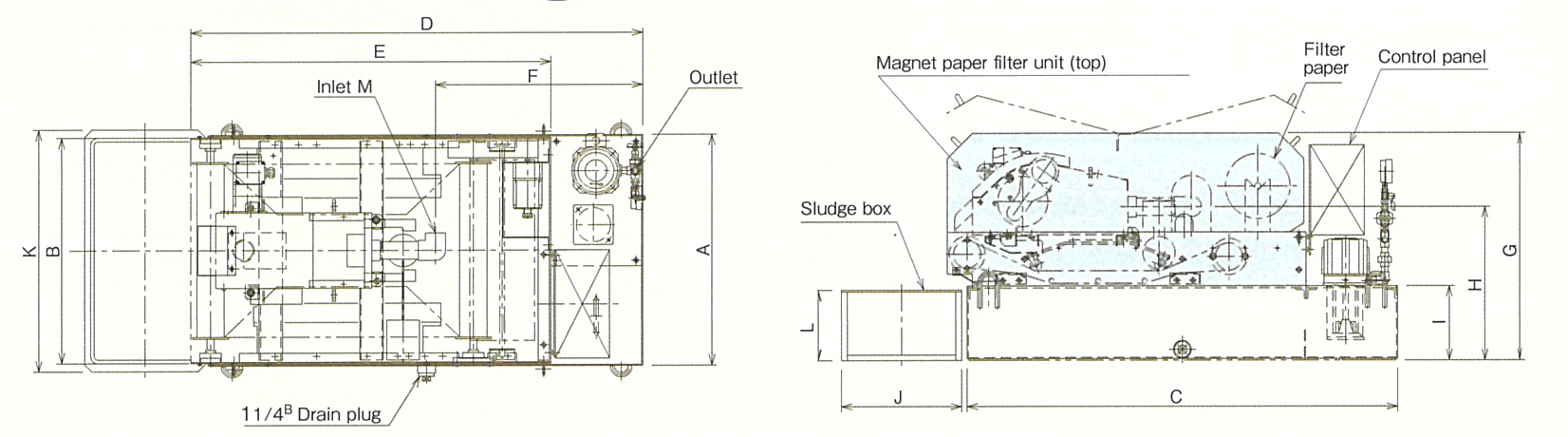

Rare earth magnet KP model / Ferrite magnet FP model magnet paper filter

- This unit combines FINE MAG (magnetic separator) with a paper filter.

- Use of both FINE MAG and a paper filter greatly reduces filter paper consumption and lowers running cost.

Applications

- Various grinding machines

- Honing machines

- Superfinishing machines

- Cold rolling machines

- Wire drawing machines

- Washing machines

Magnetic

sludge

Structure

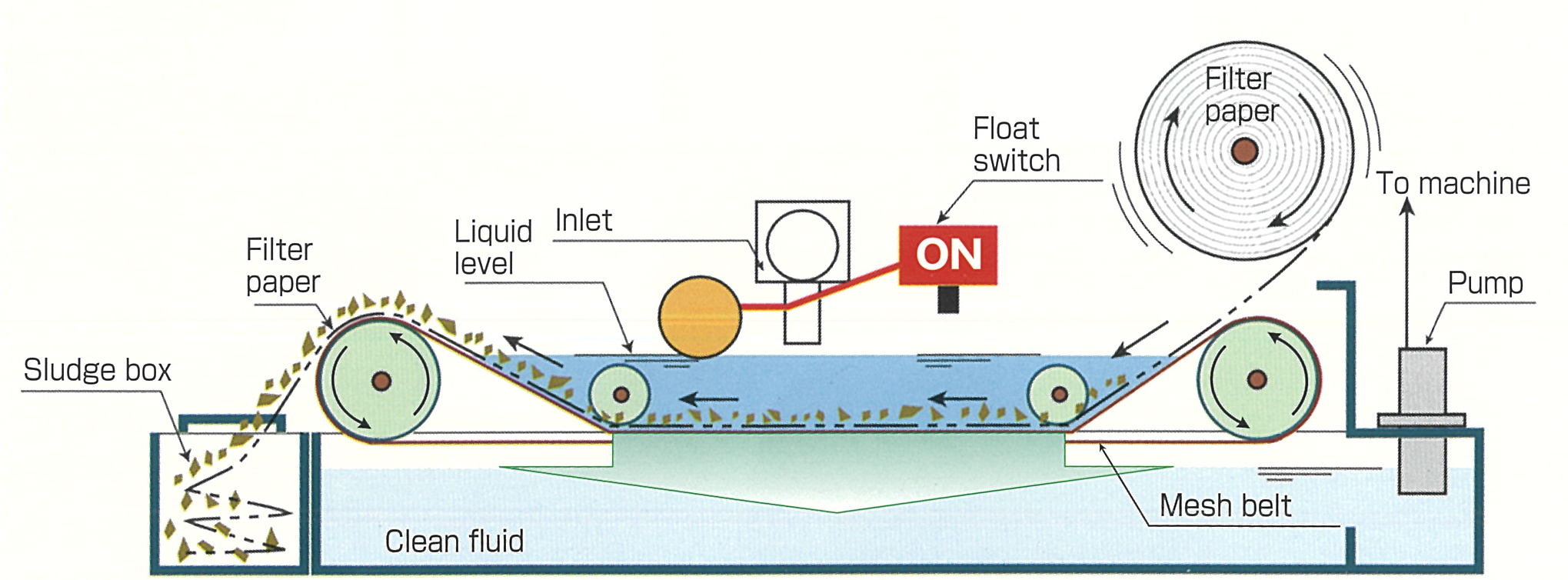

- Dirty coolant is filtered once through the magnet separator and then for the second time through the paper filter.

- When the paper filter is clogged, the coolant will rise until the float switch is turned on and a new paper filter will roll out.

- When the coolant level drops back down, the float switch is turned off and the paper filter will stop rolling.

Option

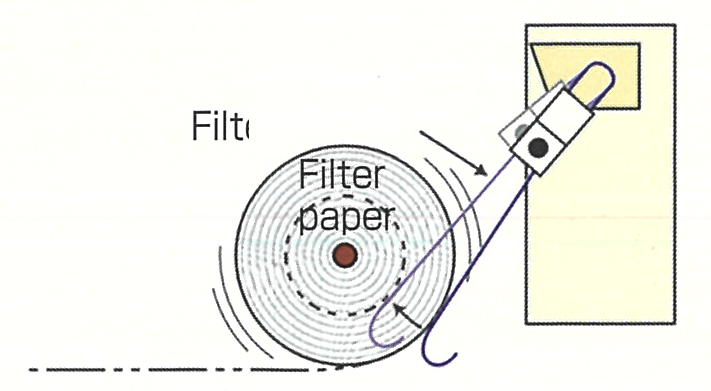

Filter Paper Decrease Detector (Limit switch type)

Detects when remainder of paper is running low.

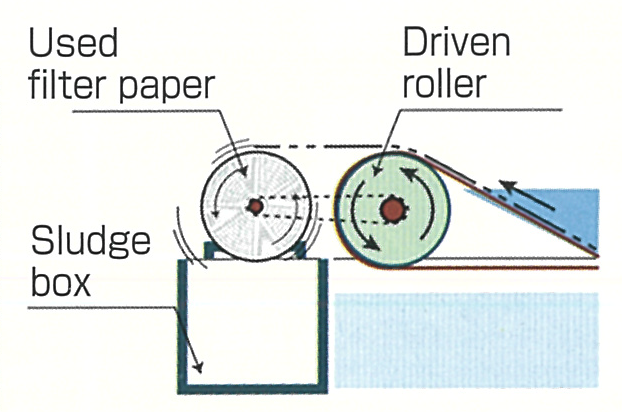

Filter Paper Take-UP Roller

Rolls up used filter paper automatically.

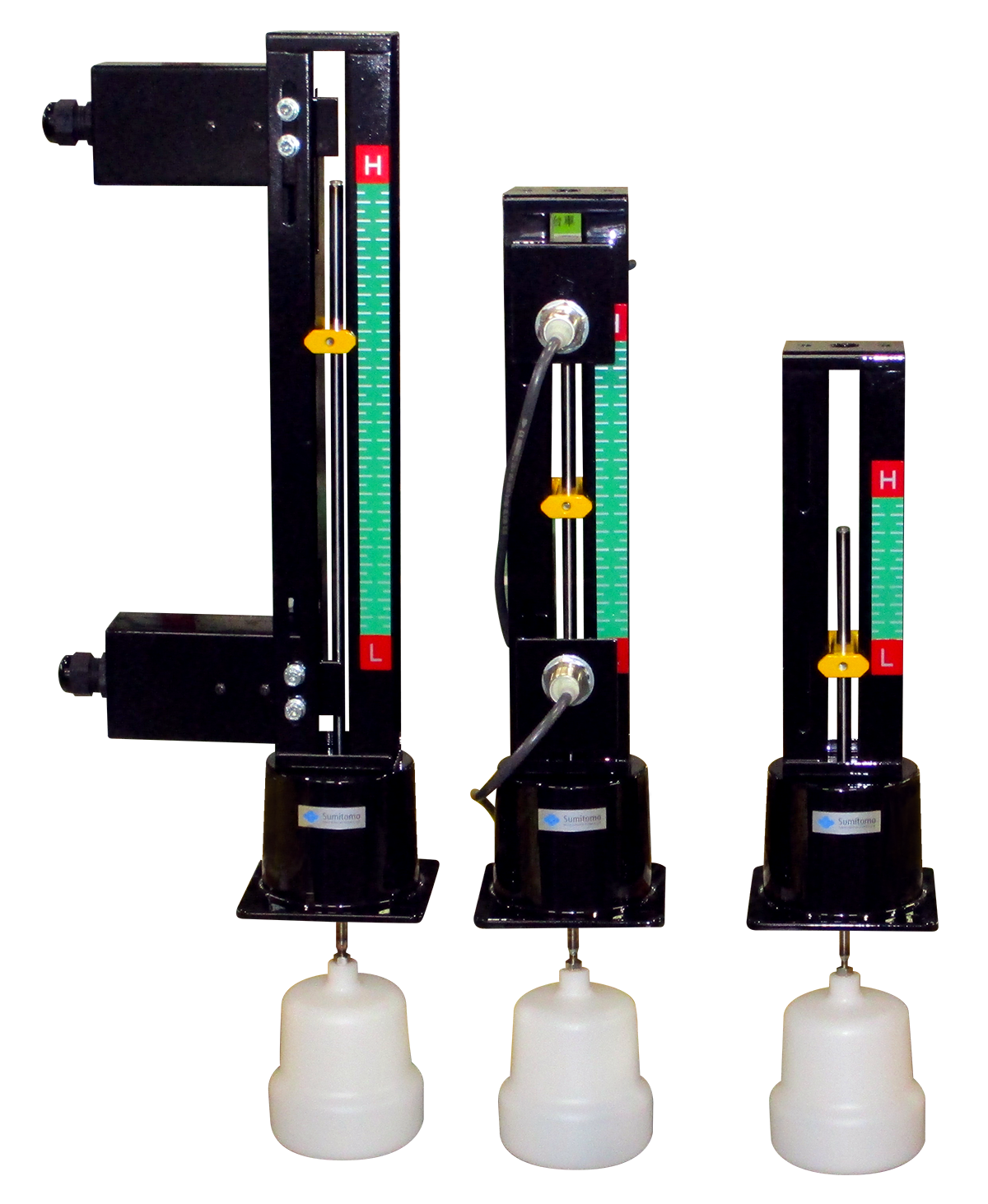

Fluid Level Gauge

Visual type limit switch type, and proximitysensor type are available.

High-capacity Paper Filter SP-700EX / 1000EX / 1300EX

Most suitable paper filter for large flow volume processes (pelletizers, etc)

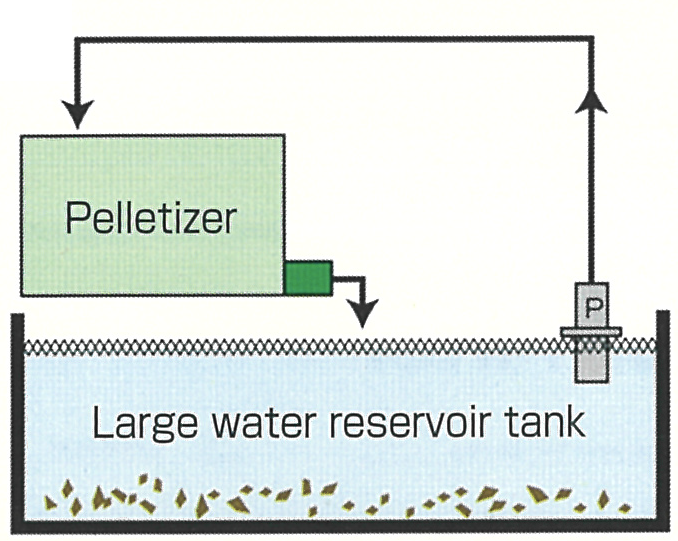

Example

Machine/Pelletizer

Before

Scum generated during product process was filtered by a metal mesh. After that plain sendimentation was performed in a large reservoir tank and upper clear layer of water was re-used.

- Large tank required wide instllation space.

- tank required frequent cleaning

- Large number of defective products were generated.

- Required frequent water exchange.

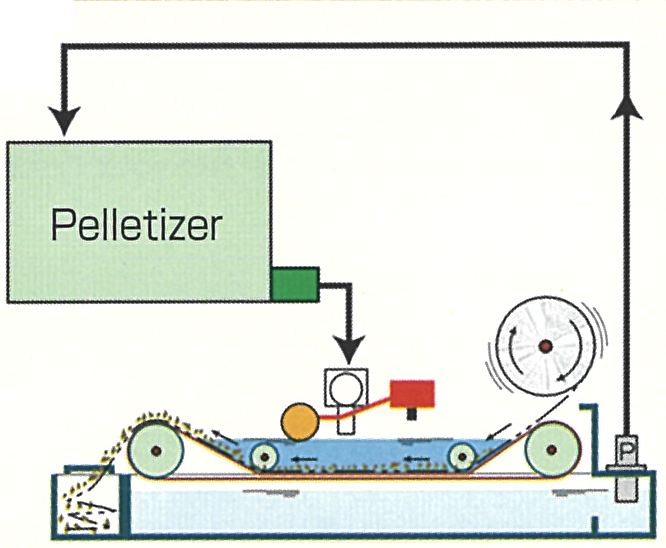

After

Saved manpower and space by installing the paper filter.

- Less space required.

- Less cleaning of tank required.

- Fewer defective products generated.

- Longer fluid life.

Paper filter

Use of Sumitomo Heavy Industries Finetech’s genuine filter paper as optimal for this product is recommended.

Selection Criteria

- Temperature of coolant used

Below 50°C – #50□□

50°C or higher and 80°C or higher – #60□□ - PH concentration

Acidic (3 to 5) – #60□□

Neutral (6 to 8) – #50□□

Alkaline (9 to 12) – #60□□

*The inner diameter of the roll core is 58 mm.

*If the temperature of the coolant is 50°C or higher, use PVC roll core.

| Item No. | Mesh size (µ) |

Material | Strength N/5cm | |

|---|---|---|---|---|

| Vertical | Horizontal | |||

| 5010 | 10 | Rayon | 174.3 | 53.6 |

| 5020 | 20 | 〃 | 122.9 | 37.2 |

| 5025 | 25 | 〃 | 91.7 | 30.8 |

| 5030 | 30 | 〃 | 76.7 | 20.6 |

| 5040 | 40 | 〃 | 48.1 | 13.7 |

| 5050 | 50 | 〃 | 89.5 | 16.2 |

| 5060 | 60 | 〃 | 85.8 | 29.5 |

| 5086 | 86 | 〃 | 67.6 | 20.0 |

| 5095 | 95 | 〃 | 73.4 | 27.0 |

| 6010 | 10 | Polyester | 225.0 | 91.0 |

| 6020 | 20 | 〃 | 159.0 | 53.0 |

| 6030 | 30 | 〃 | 110.0 | 36.0 |

| 6040 | 40 | 〃 | 82.0 | 28.0 |

Product characteristics

Standard specifications

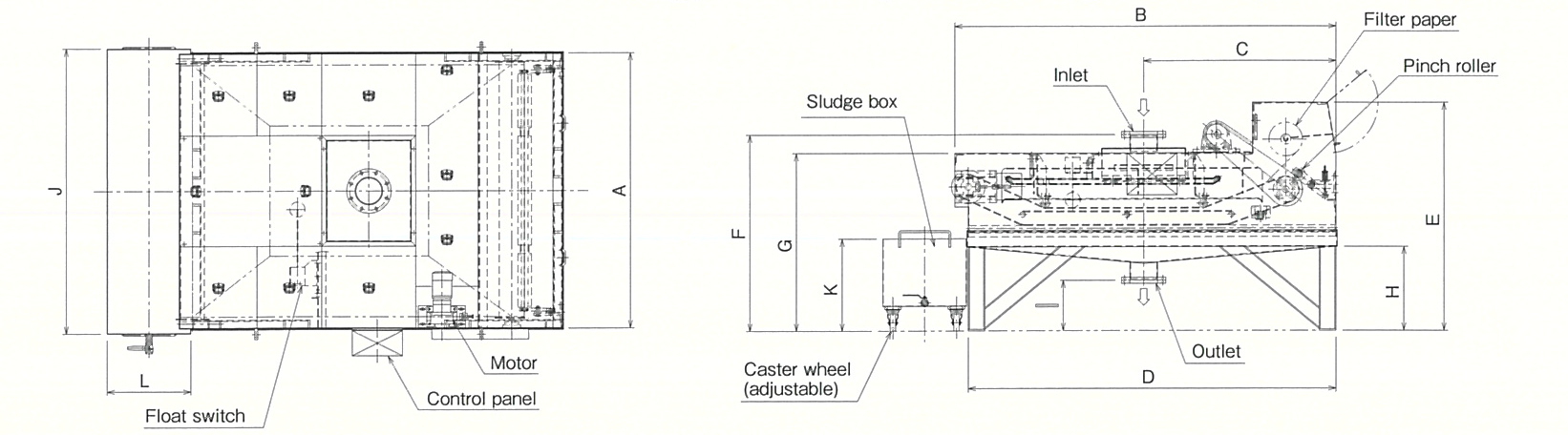

SP series Paper Filter

| Model | Processing volume | Motor | Width (mm) | Length (mm) | Height (mm) | Inlet (Rp) | Tank capacity | Filter paper width | Weight | Sludge box (plastic)(mm) | Standard equipped pump output | Exhaust port (Rp) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ℓ/min | (W) | A | B | C | D | E | F | G | H | I | M | (ℓ) | (mm) | (kg) | J | K | L | 50Hz | 60Hz | 50Hz | 60Hz | |

| SP-4-1 | 40 | 25 | 640 | 625 | 1200 | 1255 | 1000 | 835 | 601 | 400 | 206 | 2B | 120 | 500 | 155 | 335 | 670 | 195 | 100W | 100W | 3/8B | 3/8B |

| SP-6-1 | 60 | 25 | 640 | 625 | 1400 | 1455 | 1130 | 970 | 601 | 400 | 206 | 2B | 140 | 500 | 165 | 335 | 670 | 195 | 180W | 100W | 1/2B | 3/8B |

| SP-8-1 | 80 | 25 | 890 | 875 | 1350 | 1405 | 1000 | 985 | 601 | 400 | 206 | 2B | 190 | 750 | 190 | 335 | 1005 | 195 | 180W | 180W | 1/2B | 1/2B |

| SP-12-1 | 120 | 25 | 890 | 875 | 1700 | 1755 | 1130 | 1270 | 641 | 440 | 246 | 2B | 310 | 750 | 235 | 335 | 1005 | 195 | 400W | 250W | 1B | 3/4B |

| SP-18-1 | 180 | 25 | 1050 | 1035 | 1770 | 1900 | 1260 | 1295 | 770 | 575 | 299 | 4B | 470 | 900 | 330 | 335 | 1005 | 195 | 750W | 400W | 1B | 1B |

| SP-24-1 | 240 | 25 | 1050 | 1035 | 2370 | 2500 | 1430 | 1810 | 770 | 575 | 299 | 4B | 630 | 900 | 405 | 335 | 1005 | 195 | 400W×2 | 250W×2 | 1B | 3/4B |

| SP-36-1 | 360 | 25 | 1520 | 1035 | 2370 | 2500 | 1950 | 1550 | 770 | 575 | 299 | 4B | 920 | 900 | 575 | 335 | 1005 | 195 | 750W×2 | 400W×2 | 1B | 1B |

| SP-50-1 | 500 | 90 | 1050 | 1035 | 3000 | 3120 | 2450 | 1920 | 950 | 735 | 409 | 4B | 1150 | 900 | 733 | 500 | 1050 | 500 | 1500W | 1500W | 2 1/2B | 2 1/2B |

※1. Processing volume is for passage of plain water through 30 μ filter paper at normal temperature.

Rare earth magnet KP / Ferrite magnet FP series Magnet Paper Filter

| Model | Processing volume | Motor | Width (mm) | Length (mm) | Height (mm) | Inlet (Rp) | Tank capacity | Filter paper width | Weight | Sludge box (plastic)(mm) | Standard equipped pump output | Exhaust port (Rp) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ℓ/min | (W) | A | B | C | D | E | F | G | H | I | M | (ℓ) | (mm) | (kg) | J | K | L | 50Hz | 60Hz | 50Hz | 60Hz | |

| KP/FP-4B-1 | 40 | 25 | 640 | 625 | 1200 | 1255 | 1000 | 575 | 630 | 425 | 206 | 1 1/2B | 120 | 500 | 180 | 335 | 670 | 195 | 100W | 100W | 3/8B | 3/8B |

| KP/FP-6B-1 | 60 | 25 | 640 | 625 | 1400 | 1455 | 1130 | 695 | 630 | 425 | 206 | 2B | 140 | 500 | 195 | 335 | 670 | 195 | 180W | 100W | 1/2B | 3/8B |

| KP/FP-8B-1 | 80 | 25 | 890 | 875 | 1350 | 1405 | 1000 | 725 | 660 | 457 | 206 | 2B | 190 | 750 | 225 | 335 | 1005 | 195 | 180W | 180W | 1/2B | 1/2B |

| KP/FP-12B-1 | 120 | 25 | 890 | 875 | 1700 | 1755 | 1130 | 995 | 710 | 497 | 246 | 2 1/2B | 310 | 750 | 280 | 335 | 1005 | 195 | 400W | 250W | 1B | 3/4B |

| KP/FP-18B-1 | 180 | 25 | 1050 | 1035 | 1770 | 1900 | 1260 | 1069 | 820 | 606 | 299 | 3B | 470 | 900 | 365 | 335 | 1005 | 195 | 750W | 400W | 1B | 1B |

| KP/FP-24B-1 | 240 | 25 | 1050 | 1035 | 2370 | 2500 | 1430 | 1604 | 900 | 615 | 299 | 3B | 630 | 900 | 460 | 335 | 1005 | 195 | 400W×2 | 250W×2 | 1B | 3/4B |

| KP/FP-36B-1 | 360 | 25 | 1520 | 1035 | 2370 | 2500 | 1950 | 1492 | 950 | 635 | 299 | 4B | 920 | 900 | 665 | 335 | 1005 | 195 | 750W×2 | 400W×2 | 1B | 1B |

※1. Processing volume is for passage of plain water through 30 μ filter paper at normal temperature.

High-capacity Paper Filter SP-700EX / 1000EX / 1300EX

| Model | Processing volume | Motor | Width (mm) | Length (mm) | Height (mm) | Sludge box (mm) | Flange diameter(mm) | Weight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ℓ/min | (W) | A | B | C | D | E | F | G | H | I | J | K | L | Inlet | Outlet | (kg) | |

| SP-700EX | 700 | 100 | 1640 | 2280 | 1150 | 2200 | 1360 | 1170 | 1060 | 500 | 300 | 1700 | 550 | 500 | 6B | 6B | 800 |

| SP-1000EX | 1000 | 100 | 1640 | 3280 | 1610 | 3200 | 1360 | 1170 | 1060 | 500 | 300 | 1700 | 550 | 500 | 6B | 8B | 1000 |

| SP-1300EX | 1300 | 100 | 1640 | 4280 | 1610 | 4200 | 1360 | 1170 | 1060 | 500 | 300 | 1700 | 550 | 500 | 6B | 8B | 1300 |

※1.Processing volume is for passage of plain water through 30 μ filter paper at normal temperature.

※2.The motor voltage is AC200V 50/60Hz 3ph

※3.Includes one roll of filter paper.

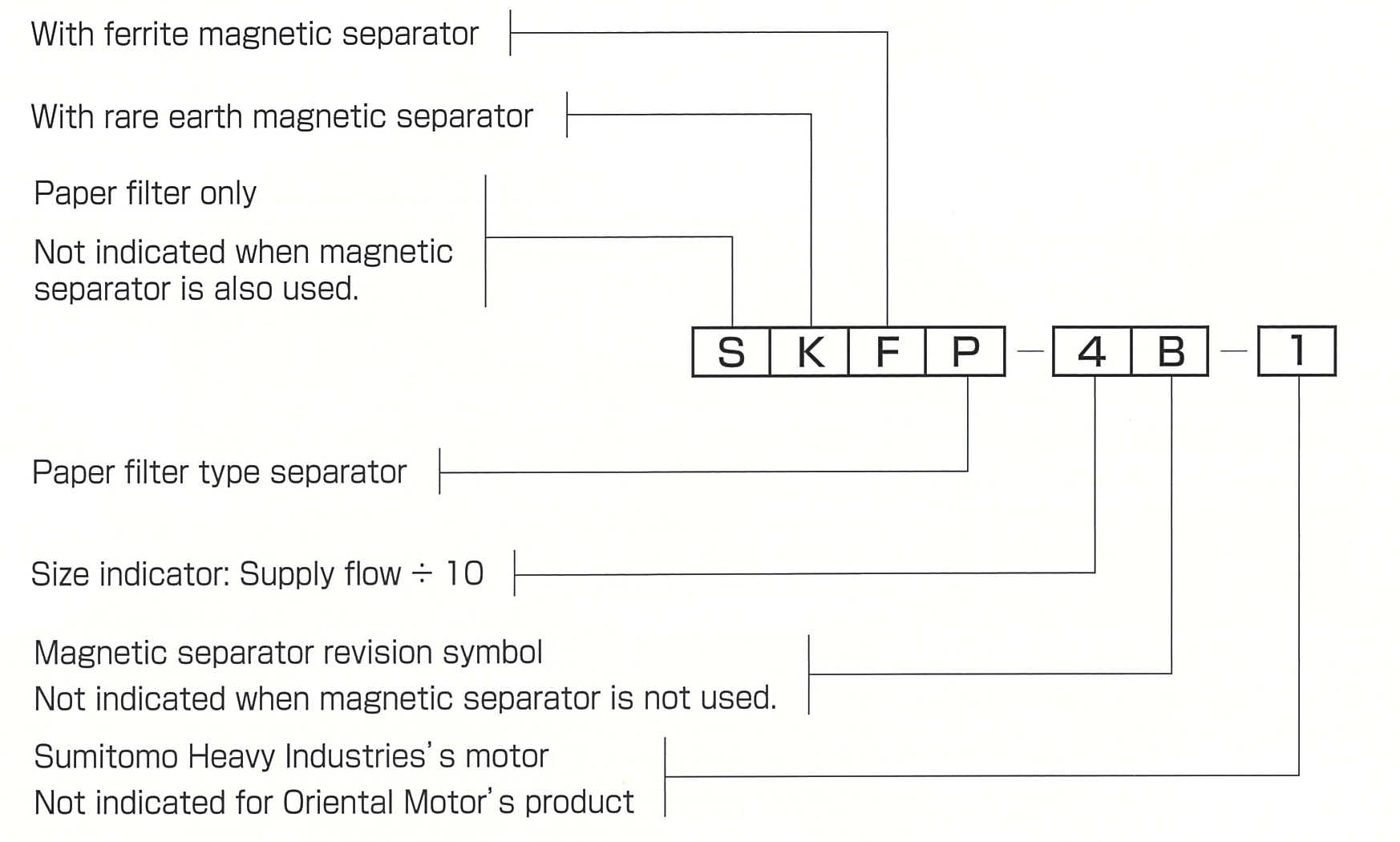

Model Code

Standard specifications

- The inlet is on the left (when viewed from the paper filter discharge side).

- Motor voltage: AC200V 50/60Hz 3ph (meets CE, UL and CCC standards)

- Includes 1 sludge box.

- Includes 1 paper filter.

Applicable scope

- Paper filter unit (upper part)

- Paper filter unit (upper) and control panel

- Paper filter unit (upper) and tank unit with control panel

Options

- Filter paper decrease detector

- Filter paper tank-up roller

- Fluid level gauge (visual type, limit switch type, and proximity sensor type are available)

Special specifications

- Different voltage: AC380V・400V・415V・440V 50/60Hz (CE・CCC Compliant)

- Right inlet specification

- Combined use with a magnetic separator that has a processing volume of 500 L/min and higher.

※Please contact us for further details.

Excluding high-capacity type.