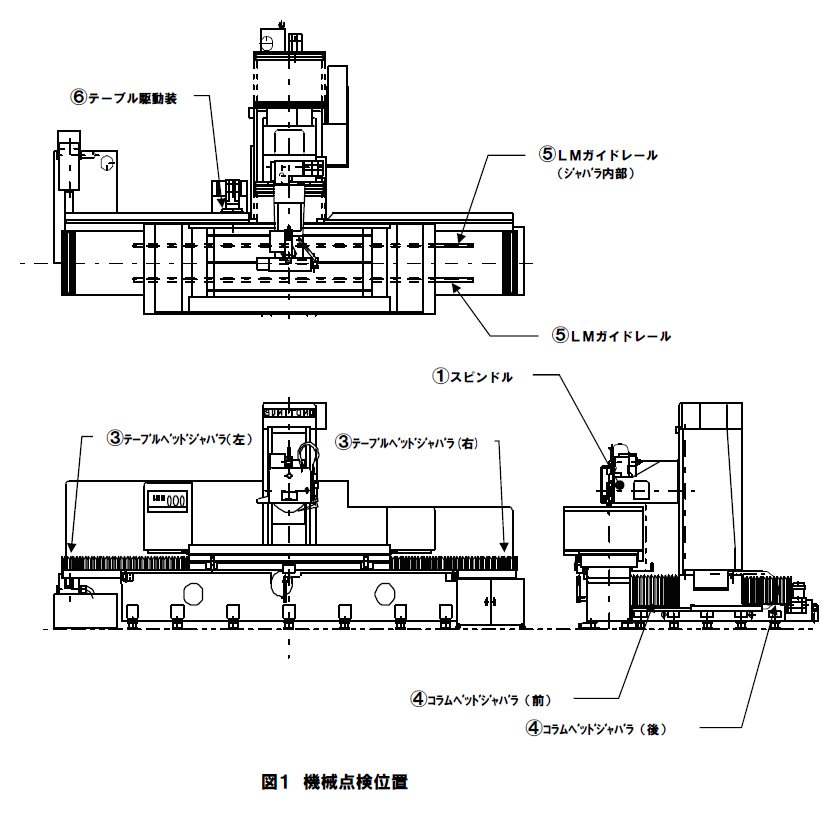

Proposals for preventive maintenance: CNC Precision Surface Grinding Machine – KSH Series

Self-diagnosis: Precision Surface Grinding Machine KSH Series self-diagnosis menu

Every part of the machine is a consumable, so it may degrade and be damaged. Using the machine under such circumstances may cause it to break down.

To prevent machine breakdowns, use the self-diagnosis menu to determine if it is necessary to replace or repair parts.

Inspection items

- Spindle

- Hydrostatic bearing spindle

- Bed bellows

- Column bed bellows

- Linear guides

- Table drive unit

If any of the following applies, a machine overhaul may be necessary.

First, please check each of the following items.

①Spindle

- The operation time has exceeded 10,000 hours.

- There is a strange noise when the spindle is rotating.

- It feels strange when it is rotated manually.

②Hydrostatic bearing spindle

- 20% or more of the pocket pressure is down compared to the start.

- The filter is clogged.

- There is abnormal heat generated.

- There is a strange noise when the Hydrostatic bearing spindle is rotating.

- It feels strange when it is rotated manually under hydrostatic pressure.

- The oil is dirty.

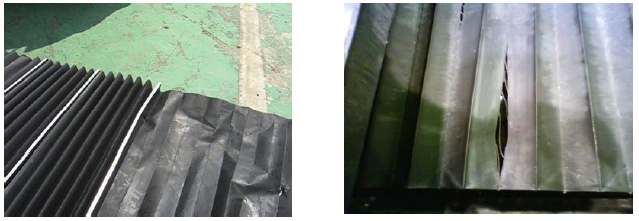

③Bed bellows (left and right)

- There is significant degradation.

- There is damage such as holes.

- It is bent.

④Column bed bellows (front and back)

- There is significant degradation.

- There is damage such as holes.

- It is bent.

The bellows is a consumable, so it may degrade and be damaged when used for a long period of

time.

Using the machine under such circumstances may cause coolant, waste, etc., to enter the bed

groove and cause the machine to break down.

Reference: Degraded/Bent/Damaged bellows

⑤Linear guides

- It feels strange when moving the table.

- Lubricating oil has not been applied to the linear guides. (No lubricating oil on the linear guides rail.)

- Rust has developed.

The Linear guides for guiding tables is hidden by the bellows, so it is not visible

usually.

As a result, operators may not notice any damage, which may lead to a major machine failure.

Reference: Scratched/Degraded Linear guidesrail

⑥Table drive unit

- There is a loud noise when it is reversed (sound of metal banging).

- There is a loud noise from the Speed reducer when the machine is running.

- The timing belt is undulated greatly when it is reversed.

Please contact us if any of the above applies.

Updating control devices that cannot be repaired

Some control devices installed in our grinding machines cannot be repaired after the production has stopped and the applicable service period has passed, even if they are broken. If a part of the device breaks down, the entire device needs to be replaced.

Some devices may take a while to prepare, so there is a risk that they may need to be stopped for a long period of time after they break down. As preventive maintenance, we recommend updating control devices before that happens.

The list below is an example of such devices. We can offer solutions individually if you have questions or requests.

List of control devices that cannot be repaired

| Model | Uses | Name | Model | Manufacturer |

|---|---|---|---|---|

| KSH | Control device for spindle drive | Inverter | FREQROL-A200(E) | Mitsubishi Electric |

| FREQROL-Z200 | ||||

| Control device for magnetic chucks | Contourator | NS2-5FE、NS2-10FET | Fuji Jikoh | |

| NS2-5FD | ||||

| NS2-5FC、NS2-10FC | ||||

| NS2-10GT1、NS2-20G |